Best Duramax Engine: Unveiling the Top Performer for Reliability and Efficiency

When it comes to powerful diesel engines, the conversation often centers on one key contender: the Duramax. But which model holds the title for the best Duramax engine? Dive in as we unpack the details and crown the champion in this fierce competition.

If you just want the short answer, Duramax enthusiasts believe the best Duramax engines are often considered to be the LBZ (2006-2007) for its strength and lack of emissions restrictions, and the LML (2011-2016) for its advanced technology and improved performance. These models strike a balance between reliability, power, and modern innovations, making them favorites among Duramax enthusiasts.

But that’s just the start. In this article, we’ll dive deeper into the evolution of Duramax engines over the years to give you a complete overview.

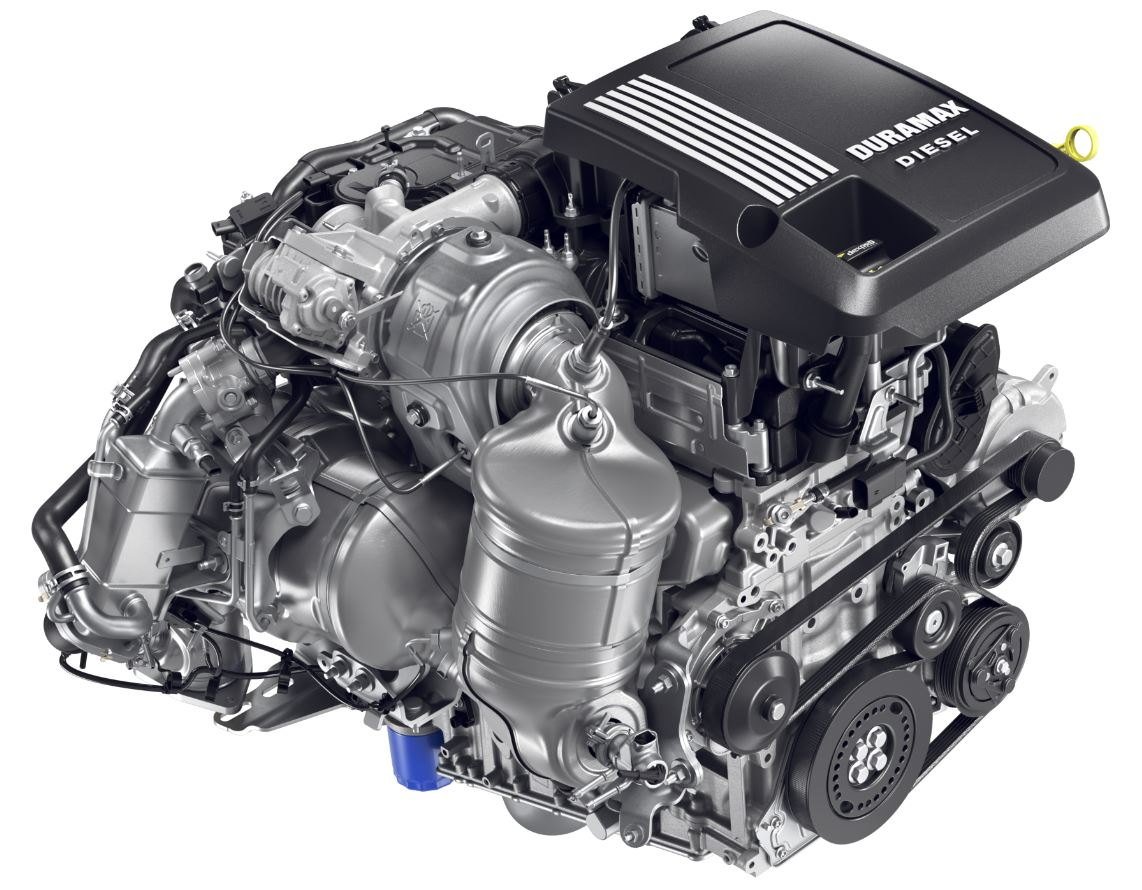

Overview of Duramax Engines

Duramax engines are a popular choice for those who need powerful and reliable diesel engines.

Manufactured by a joint venture between General Motors and Isuzu, these engines are designed for Chevrolet and GMC diesel trucks.

They offer exceptional torque and horsepower, making them perfect for heavy-duty applications such as towing and hauling.

The Duramax engine lineup includes several models, each featuring unique specifications and performance characteristics. Here’s a quick look at some of the most popular models:

- LB7 (2001-2004): The first Duramax engine produced, the LB7 is a 6.6L V-8 engine featuring a 32-valve design with 4 valves per cylinder. It comes with high-pressure common-rail direct injection and a composite cylinder head.

- LLY (2004-2006): The LLY, while similar in structure to the LB7, is known for being capable of achieving the largest amount of additional horsepower through tuning alone, second only to the most recent model, the L5P.

- LBZ (2006-2007): Offering improved performance and emissions control, the LBZ features increased horsepower and torque compared to its predecessors. This Duramax engine is often considered a favorite among diesel enthusiasts.

- LMM (2007-2010): The LMM comes equipped with a diesel particulate filter to improve emissions. This engine provides solid performance and reliability, though some consider it slightly less powerful than the LBZ.

- LML (2011-2016): The LML includes significant improvements in performance, fuel economy, and emissions control. It was introduced to meet stringent emission standards and provide a more environmentally-friendly option for heavy-duty trucking.

- L5P (2017-present): The most recent addition to the Duramax family, the L5P boasts the highest horsepower and torque ratings of any Duramax engine so far. Its advanced design offers durability and reliability, making it an ideal choice for heavy-duty applications.

Some common issues associated with Duramax engines include injector failure and overheating.

However, these engines can provide long-lasting power and performance with proper maintenance and care.

When considering which Duramax engine is best for your needs, evaluating your individual requirements and preferences is essential.

Consider factors such as the engine’s power capabilities, emissions control, fuel efficiency, and longevity.

Each Duramax engine has its unique strengths and weaknesses, and selecting the right one for your truck can ultimately enhance your driving experience and overall satisfaction.

Different Generations and Models

LB7 Model

The LB7 model, introduced in 2001, was the first generation of Duramax engines. This 6.6-liter V8 engine, developed by Isuzu and General Motors, provided excellent diesel performance and fuel efficiency.

However, the LB7 had a common issue with injector failures, which could be an expensive repair costing $3,000 to $4,000.

LLY Model

The LLY model, released in 2004, was an updated version of the LB7. General Motors made several improvements, such as adding variable geometry turbocharging for better efficiency.

The LLY engine also featured improved head gasket design and a faster ECU for better performance. Despite these advancements, the LLY still had some injection issues similar to the LB7 model.

LBZ Model

In 2006, the LBZ model replaced the LLY and offered more horsepower (360 hp) and torque (650 lb-ft).

The LBZ addressed the injector issues of previous models and provided a more robust engine overall. Key improvements included a strengthened block, connecting rods, and revised intake and exhaust systems.

Additionally, the LBZ engine came with an updated six-speed Allison automatic transmission.

LMM Model

The LMM model, introduced in 2007, was a relatively minor update from the LBZ.

This model focused on complying with stricter emissions regulations, and the LMM featured a diesel particulate filter to reduce harmful emissions.

It maintained similar horsepower and torque numbers to the LBZ model, providing reliable performance.

LML Model

The LML model came to the market in 2011 and brought significant updates to the Duramax engine family.

It offered increased horsepower (397 hp) and torque (765 lb-ft), along with improved fuel efficiency. Some of the key upgrades included a high-pressure fuel system, updated engine control module, and revised exhaust gas recirculation system.

The LML also featured selective catalytic reduction technology to meet ever-evolving emission standards.

L5P Model

The L5P model, the latest Duramax generation, was introduced in 2017. It offers the best performance, with 445 horsepower and 910 lb-ft of torque.

The L5P engine features an all-new block, advanced fuel system, and an upgraded turbocharger.

This model also benefits from an improved intercooler, reduction in NOx emissions, and a refined balance of power and efficiency.

Duramax engine models through the years:

- LB7 (2001-2004)

- LLY (2004-2006)

- LBZ (2006-2007)

- LMM (2007-2011)

- LML (2011-2016)

- L5P (2017-Present)

Performance and Power

The Duramax engines are well-known for their exceptional performance and power. Various Duramax engines have been designed to provide optimal horsepower, torque, and efficiency.

In this section, we’ll discuss some key features of these engines that contribute to their outstanding performance.

One major aspect of Duramax engines is their impressive horsepower and torque output. The first generation Duramax, the 6.6L LB7 engine, produced 235 horsepower and 500 lb-ft of torque.

Over the years, these numbers have increased dramatically. In the latest iteration, the 6.6L Duramax offers 445 horsepower and 910 lb-ft of torque, which highlights the continuous improvement in power and performance.

The turbocharger technology employed in these engines is a significant contributor to the Duramax’s performance.

Several models come equipped with variable geometry turbochargers that allow for greater control over turbine speed, resulting in improved throttle response and efficiency.

Some high-performance Duramax engines also utilize triple-turbo configurations, which further enhance the engine’s power output.

Duramax engines are often paired with the reliable Allison Transmission. This transmission is specifically designed for heavy-duty applications and offers smooth gear shifting and improved fuel economy.

The Duramax engine and Allison Transmission combination creates a powerful, responsive, and efficient powertrain that is ideal for Chevrolet vehicles.

Fuel economy is another essential aspect of Duramax engine performance.

Innovations like the 6.6L V8 engine and the use of intercoolers have improved fuel efficiency, making these engines popular for drivers who require power without sacrificing fuel economy.

To summarize, some key performance and power features of Duramax engines include:

- Impressive horsepower and torque output

- Advanced turbocharger technology, such as variable geometry and triple-turbo configurations

- Compatibility with the Allison Transmission for smooth gear shifting and improved fuel economy

- Use of intercoolers for enhanced efficiency

By providing powerful, efficient, and responsive performance, Duramax engines continue to be a top choice for drivers seeking optimal power and fuel economy in their Chevrolet vehicles.

Reliability and Longevity

Duramax engines are known for their reliability and longevity. With proper maintenance, you can expect a Duramax engine to last for a long time.

Here are some factors that contribute to their impressive lifespan:

- Construction: Duramax engines are built with high-quality materials such as cast iron blocks and aluminum cylinder heads, which enhance their durability and ability to withstand wear and tear.

- Maintenance: Regular maintenance, including oil changes, filter replacements, and timely repairs, can help prolong the life of your Duramax engine. By following the recommended maintenance schedule, you can prevent potential issues and ensure optimum engine performance.

Some popular Duramax engines and their key characteristics include:

- LB7 (2001 – 2004): The first generation of the V8 Duramax engine, the LB7, is known for its power and reliability. However, it had some issues with the injectors, causing rough idling and low fuel economy.

- LBZ (2006 – 2007): The LBZ is considered one of the best and most reliable Duramax engines. It is strong and durable, with the only known weakness being cracked pistons at horsepower levels over 600. This is not usually an issue for most owners.

While the price of a Duramax engine may be higher than some other diesel engines on the market, its reliability and longevity can offset the initial cost.

| Duramax Engine | Lifespan | Price | Maintenance |

|---|---|---|---|

| LB7 | Good | Moderate | Regular injector replacement and maintenance required |

| LBZ | Excellent | Moderate | Regular maintenance required, fewer known issues |

In conclusion, factors such as construction, maintenance, and the specific engine model play crucial roles when considering the reliability and longevity of a Duramax engine.

By keeping up with recommended maintenance procedures and investing in a reliable model like the LBZ, you can maximize the lifespan and performance of your Duramax engine.

Share Your Insights With US

Did we forget something, get something right (or wrong)? We’d love to hear your insights! Share your automotive experiences based on our article in the comments below. Your input enriches our community’s knowledge. Thanks in advance for sharing!

Common Issues and Weaknesses

Overheating Problems

Overheating is common in older Duramax engines, especially in the LLY models. These issues often occur when the truck is being worked hard with a heavier trailer or on a hot summer day.

These engines’ stock air intake system can contribute to a hotter running LLY Duramax.

To avoid overheating, you can:

- Regularly check and maintain the coolant level

- Keep your radiator clean and free from debris

- Install an upgraded air intake system

Injector Failures

Injector failures are prevalent in some Duramax engines, stemming from issues with the injection pump and cracks in the fuel filter housing.

These problems can cause air to get into the fuel lines, leading to poor engine performance. Regular maintenance can help prevent injector failures, such as:

- Inspecting and replacing old or worn fuel filters

- Addressing any fuel system leaks promptly

- Installing a lift pump to alleviate issues with the injection pump

Weak Tie Rods Issues

Weak tie rods can be a problem in older Duramax engines, causing issues with steering and suspension.

Upgrading your tie rods to a more robust aftermarket version can help eliminate these issues. Besides, you should also:

- Periodically inspect your tie rods for signs of wear or damage

- Ensure proper alignment and tire wear to reduce stress on tie rods

- Get regular check-ups from a reputable mechanic familiar with your specific Duramax model

CP4.2 Failures

The Duramax LML engines use a CP4.2 injection pump, which unfortunately suffers from relatively common failures.

These failures can cause significant internal engine damage due to contamination from metal debris. To mitigate this risk, consider the following:

- Regularly change your fuel filters and use high-quality fuel

- Add a fuel additive to help lubricate the CP4.2 pump

- Install a CP3 conversion kit to replace the problematic CP4.2 pump

By staying vigilant in your maintenance routine and addressing potential issues early, you can keep your Duramax engine running smoothly and avoid costly repairs.

Emissions Control and Regulations

Emissions control is a crucial aspect for diesel engines, as they help in reducing the environmental impact caused by harmful pollutants.

For Duramax engines, multiple systems work together to ensure compliance with emissions standards and regulations.

Diesel Particulate Filter (DPF): The DPF is an essential component of Duramax engines responsible for trapping and reducing the emissions of diesel particulates.

Over time, the filter becomes saturated with particulates and needs to go through a process called regeneration, which burns off the trapped particles.

It is vital to maintain the DPF to ensure optimal performance and reduced emissions.

Exhaust Gas Recirculation (EGR): EGR is another critical emissions control component on Duramax engines. It works by recirculating a portion of exhaust gases back into the engine’s intake, reducing the production of harmful nitrogen oxides.

Proper functioning of the EGR system directly contributes to the engine complying with emissions regulations.

Diesel Exhaust Fluid (DEF): DEF is a crucial additive used in modern Duramax engines to meet emissions standards.

DEF and selective catalytic reduction (SCR) systems work together to reduce the emissions of harmful nitrogen oxides by converting them into harmless nitrogen and water vapor.

Oxidation Catalyst: An oxidation catalyst is present in Duramax engines to oxidize unburned hydrocarbons and carbon monoxide in the exhaust, converting them into less harmful substances such as carbon dioxide and water vapor.

In addition to these critical emissions control components, Duramax engines must also comply with various emissions standards and regulations. Some of these include:

- Federal standards, such as the EPA’s Tier 3 and Tier 4 regulations

- State-specific standards, particularly the California Air Resources Board (CARB) regulations

To successfully navigate through the complexities of emissions control and regulations, it is essential to maintain your Duramax engine properly and ensure all components are functioning efficiently.

Doing so allows you to enjoy a cleaner, more environmentally-friendly driving experience while remaining compliant with emissions requirements.

Fuel System and Design

Common-Rail Injection System

The Duramax engines utilize a high-pressure common-rail injection system that contributes significantly to their efficiency and performance.

This system allows for a more precise fuel metering compared to older systems. Key benefits of a common-rail injection system include:

- Improved combustion control

- Reduced emissions

- Increased fuel efficiency

- Lower engine noise

In Duramax engines, the common-rail system operates at high pressures (up to 30,000 PSI), which contributes to a cleaner, more efficient combustion process.

Lift Pump and Injection Pump

Duramax engines are equipped with a lift pump and an injection pump. The lift pump carries the fuel from your fuel tank and delivers it to the injection pump.

In Duramax engines, the injection pump is typically a Bosch CP3, which is well-known for its reliability. Some of the features of the injection pump include:

- Gear-driven via cam gear

- Solid construction, contributing to durability

- High-pressure capability

The fuel injectors in the Duramax engine also play an essential role in the performance. They are responsible for spraying the fuel into the combustion chamber in a precise manner.

However, some earlier Duramax engines, such as the LB7, experienced reliability issues with their injectors. Later models made significant improvements in this area.

Fuel Economy and Efficiency

One key factor contributing to Duramax engines’ popularity is their fuel economy and efficiency.

These engines achieve an impressive balance between performance and fuel consumption by utilizing advanced technologies like common-rail injection systems and highly efficient fuel pumps.

Some factors affecting fuel economy in Duramax engines include:

- Engine design (engine block, cylinder head, piston, and rings)

- Compression ratio

- Turbocharging

- Intercooling system

The combination of these factors allows Duramax engines to deliver both impressive power and fuel efficiency, making them a top choice for diesel truck enthusiasts.

Vehicles Using Duramax Engines

Duramax engines have been the powerhouses of choice for many General Motors vehicles over the years.

These engines have found their way under the hoods of various trucks and vans. In this section, we’ll discuss some of the vehicles that are or have been powered by Duramax engines.

Chevrolet Silverado / GMC Sierra

The Chevy Silverado and its sibling, the GMC Sierra, are some of the most prevalent vehicles using Duramax engines.

These popular full-sized pickup trucks have utilized several different generations of Duramax engines spanning from the early 2000s to the present day.

- LB7 (2001-2004)

- LLY (2004-2006)

- LBZ (2006-2007)

- LMM (2007-2010)

- LML (2011-2016)

- L5P (2017-Present)

These engines provide the power and performance necessary to keep them competitive in a market that includes formidable rivals like the Ford F-Series and Ram pickups.

Chevrolet Kodiak / GMC TopKick

In addition to the Silverado and Sierra, Duramax engines were also used in the Chevrolet Kodiak and GMC TopKick medium-duty trucks. These trucks were built to handle heavy-duty tasks and featured the same engines as the Silverado and Sierra.

Vans

Duramax engines have also found a home in GM’s popular work vans. These engines give owners the reliability and power they need to handle heavy loads and long days on the job.

In summary, Duramax engines have powered numerous vehicles across the GM lineup over the years, giving Chevy and GMC vehicles a competitive edge in the market.

The combination of power and reliability has made the Duramax a popular choice for many, and it continues to be an essential part of the GM lineup today.

Materials and Construction

Duramax engines are known for their robust materials and construction techniques, ensuring reliable performance and durability.

This section will examine the materials commonly used in Duramax engines and their impact on performance and reliability.

Most Duramax engine blocks are cast iron, providing excellent strength and durability. This material ensures that the engine can handle increased power and torque levels without risking cracks or other damage.

On top of the cast iron engine blocks, the Duramax engines use cast-aluminum heads.

The use of aluminum in Duramax engines is not limited to the heads. When it comes to valve covers, they utilize cast aluminum as well.

This material offers several advantages, including reduced weight and improved heat dissipation. In turn, these benefits lead to better overall performance and efficiency.

Some essential engine components include:

- Connecting rods

- Crankshaft

The connecting rods in Duramax engines are typically made of forged steel, providing excellent strength and longevity.

Forged steel can handle the forces exerted within the engine, ensuring that your Duramax engine performs exceptionally well under various driving conditions.

The crankshaft in Duramax engines is another critical component made of forged steel. This material choice offers added strength and durability to handle the engine’s high torque levels.

Now let’s discuss the suspension system that supports the power and weight of a Duramax engine:

Duramax-powered vehicles usually come equipped with an Independent Front Suspension (IFS) system. IFS suspension provides a smoother and more stable ride compared to solid axle suspension systems.

This type of suspension allows each wheel to react independently to road imperfections, improving driving dynamics and comfort.

Summary of Key Materials:

- Cast iron: Engine blocks

- Cast-aluminum: Heads, valve covers

- Forged steel: Connecting rods, crankshaft

By using these materials and construction methods, Duramax engines ensure exceptional performance and durability that can handle demanding conditions and heavy workloads.

Airflow and Cooling System

A well-functioning airflow and cooling system is essential for your Duramax engine, especially the 2006-2007 models, to prevent overheating, maintain performance, and extend the engine’s lifespan. Here is what you need to know:

Airflow: To keep your Duramax engine cool and running efficiently, optimal airflow is critical. A cold air intake system can significantly improve your engine’s airflow, which helps maintain a more consistent temperature.

Duramax engines’ recommended cold air intakes include the K&N Cold Air Intake Kit 57-3050, Spectre Performance Air Intake Kit SPE-9904, and K&N Cold Air Intake Kit 57-3077.

Cooling Techniques: Advanced cooling techniques can enhance your Duramax engine’s performance.

By regulating the temperature within the engine, advanced cooling techniques reduce the risk of overheating issues and maintain optimal performance levels.

For example, the GM 3.0L Duramax Diesel Engine utilizes advanced cooling techniques for efficient heat management and increased reliability.

Overheating Issues: A few reasons for overheating issues in Duramax engines may include:

- Air in the cooling system

- A malfunctioning thermostat

- Blocked or damaged radiators

Addressing these issues as soon as possible is crucial to prevent severe damage to your engine.

To ensure the durability and reliability of your Duramax engine, it is essential to consider upgrading your airflow and cooling system.

These measures can improve your engine’s performance, maintain a stable temperature, and minimize the risk of overheating issues.

Tuning and Enhancement

When it comes to enhancing the performance of your Duramax engine, tuning is an essential factor. Tuning can significantly improve your engine’s horsepower, torque, and overall efficiency.

This section will discuss the benefits of tuning and some features you should look for in a good tuning setup.

One of the primary advantages of tuning is the substantial increase in horsepower and torque, allowing your engine to perform better in various situations such as towing, acceleration, and fuel economy.

As a result, investing in a proper tuning setup can pay for itself in the long run by saving on fuel costs and enhancing the engine’s longevity.

There are several features that you should consider when looking for the best Duramax tuning setup:

- Throttle Response: A good tuning setup will improve the throttle response, giving you more control over your vehicle’s performance. This is especially important when towing or accelerating.

- Fuel Economy: A well-tuned engine should lead to better fuel efficiency, making it more cost-effective and environmentally friendly.

- Custom Tunes: Look for tuners that offer customizable tunes, allowing you to tailor the settings to your specific needs for optimal performance.

There are numerous tuning options available in the market. To help you choose the best one for your Duramax engine, here are five popular tuners based on performance and customer reviews:

- Duramaxtuner – Offers customizable tunes with the EZLynk platform, providing a comprehensive tuning solution.

- Hypertech – Known for its easy-to-use tuners that provide a noticeable difference in power and fuel economy.

- SCT – A popular flash tuner with a variety of performance settings and customizability.

- Edge Products – Offers a range of tuning products, with options for different budgets and user experience levels.

- Banks Power – Known for their quality and reliable tuning products that deliver impressive power gains.

When selecting a tuner, ensure it is compatible with your specific engine model and consider your desired performance enhancements.

Investing in a quality tuner and keeping the tuning features above in mind can significantly improve your Duramax engine’s performance and efficiency.

Towing Capacity

When considering the best Duramax engine for towing capacity, it’s essential to compare the different models and their capabilities. Duramax engines have come a long way since their introduction, offering increased horsepower, torque, and overall towing capacity throughout the years.

- LB7 (2001-2004): The first-generation Duramax engine, the LB7, was capable of producing 235 horsepower and 500 lb-ft of torque. While impressive at the time, it falls short compared to later models.

- LLY (2004.5-2006): The LLY model is similar to the LB7 in structure and shared a lack of emissions controls. Although it had a short production run, the LLY was capable of achieving the largest amount of additional horsepower from tuning alone, except for the most recent model, the L5P.

- 6.6L L5P Duramax (Current): The latest iteration of the Duramax engine, the L5P, boasts an impressive 445 horsepower and 910 lb-ft of torque. This increase in power and capability allows for significantly better towing ratings and performance.

To further illustrate the towing capacity of different Duramax engines, here’s a table for quick comparisons:

| Engine Model | Horsepower | Torque | Estimated Towing Capacity |

|---|---|---|---|

| LB7 | 235 HP | 500 lb-ft | 10,000 – 12,000 lbs |

| LLY | 310 HP | 520 lb-ft | 12,000 – 14,000 lbs |

| L5P | 445 HP | 910 lb-ft | 14,500 – 18,000 lbs |

It’s important to note that specific towing capacities may vary depending on the vehicle model, configuration, and additional equipment. Therefore, always consult your vehicle’s owner’s manual or the manufacturer’s specifications for the most accurate information regarding your Duramax-equipped vehicle’s towing capacity.

By understanding the differences in towing capacity among various Duramax engine models, you can make an informed decision when selecting the best engine for your needs.

Frequently Asked Questions

What is the most reliable Duramax motor?

The most reliable Duramax motor is often considered to be the LB7, the first generation of Duramax engines that arrived in 2001. Its lack of emission control devices made it highly reliable. However, it’s important to note that reliability can vary depending on preventative maintenance and proper care.

Which Duramax models have the best performance upgrades?

Some popular Duramax models with the best performance upgrades include:

- LLY (2004.5-2005)

- LBZ (2006-2007)

- LMM (2007.5-2010)

- LML (2011-2016)

These models have many aftermarket performance parts available, such as exhaust systems, engine programmers, and air intake systems, which can help improve horsepower, torque, and fuel efficiency.

Which year had the highest quality Duramax engine?

The highest quality Duramax engines were produced between 2011 and 2016. Many of the earlier injector and fuel system issues in the 2001-2004 models were resolved, leading to increased reliability and overall quality.

How does Duramax compare to Cummins engines?

| Duramax | Cummins |

|---|---|

| V8 Configuration | Inline-6 Configuration |

| Quieter operation | Louder operation |

| Easier to work on | More difficult to work on |

| Found in GM Trucks | Found in Ram Trucks |

| More torque | Lower torque |

Both Duramax and Cummins engines have their advantages and disadvantages, but overall, they are both highly reliable and popular diesel engines in the market. Your preference may depend on the specific application and personal preference.

What makes the LBZ engine so highly regarded?

The LBZ engine is highly regarded due to its impressive power, robust design, and relatively low emissions. It features an upgraded fuel injection system and increased airflow, leading to better engine performance and reliability compared to previous models. The LBZ also did not have as many emission control devices as later models, making it easier to maintain.

Which Duramax engine is most fuel efficient?

The Duramax LML engine (2011-2016) is believed to be the most fuel-efficient Duramax engine due to its advanced technologies and emission control systems. The LML features a high-pressure common rail fuel system and advanced turbocharger technology, resulting in improved efficiency, reliability, and overall performance.