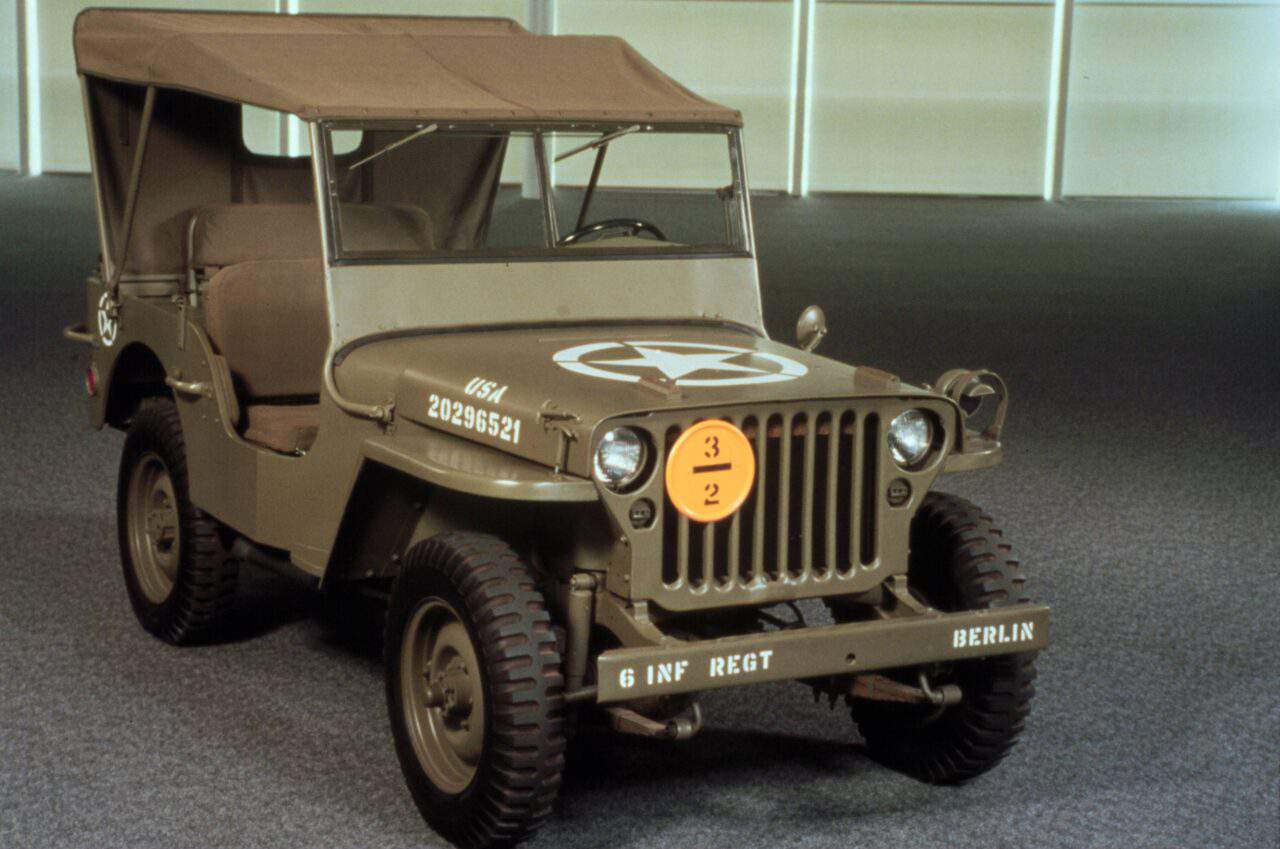

The Willys Jeep That Won the War: How a Simple Design Became the Backbone of U.S. Military Mobility

Built for speed, toughness, and ease of repair, the Willys Jeep was the unsung hero that carried soldiers through the toughest terrains of World War II.

In the heat of World War II, the U.S. Army needed a vehicle that could navigate tough terrain, be easily repaired, and—most importantly—be assembled rapidly.

Enter the Willys Jeep, a rugged masterpiece of straightforward engineering that became the backbone of American military mobility.

Designed by the Willys-Overland Company, the Jeep wasn’t just another military vehicle; it was an all-terrain workhorse built with simplicity in mind. This simplicity wasn’t just about cost-saving—it was a matter of survival.

How the Willys Jeep was born

The story of the Jeep began in 1940 when the U.S. military called for a small, light, and fast reconnaissance vehicle that could handle off-road conditions.

The challenge was clear: the vehicle needed to be assembled quickly and repaired even quicker. The engineers at Willys and its competitor, Ford, set to work creating a machine that met the military’s demanding requirements.

What made the Jeep truly special was its uncomplicated design. The engineers knew that on the battlefield, maintenance could be a matter of life and death. A broken-down vehicle could stall an entire mission.

With this in mind, they built the Jeep with modular parts, meaning soldiers could replace faulty components with relative ease. The four-cylinder engine was simple but powerful, pushing the Jeep through mud, snow, and rough landscapes without a fuss.

This versatility still wows automotive fans today. The following video shows just how easy it was to piece together.

Another critical feature was the vehicle’s flat, slab-sided body and lightweight frame. Not only did this make the Jeep fast, but it also meant it could be assembled from scratch in less than two days, and disassembled and shipped in parts when necessary.

This was ideal for the military, as the Jeep could be sent in crates and reassembled in the field by soldiers without requiring specialized tools or expertise.

Beyond its utilitarian design, the Jeep’s assembly process became a legendary feat. On production lines in the U.S., the Jeep was made in such a way that workers could piece together the vehicles at lightning speed.

By the end of the war, over 640,000 Jeeps had been produced—more than any other vehicle at the time.

From then on, the Willy Jeep stood the test of time. In fact, it has become so iconic that, even today, its design continues to be the reference for offroaders.

It’s that very same design that people have come to love. The Willys Jeep wouldn’t only make history during the war. It’s evolution, the CJ (or Civilian Jeep) would even cross the toughest terrains in the Amazon, in the first-ever Camel Trophy.

Granted, these Jeeps were in fact Fords, produced under Brazilian licenses, but fascinating nonetheless.

The Willys Jeep even became the stuff of legend. Every automotive enthusiast has heard the legend that you could buy a disassembled Willys Jeep in a crate for $50. Unfortunately, the chances of that happening were very slim.

The Icon That Still Survives: The Willys Jeep

Ultimately, the Willys Jeep’s design philosophy was one of extreme pragmatism: build it simple, make it tough, and ensure it could be put together rapidly.

It’s so durable that many still drive today. These two dudes took it to a dealership for service!

It wasn’t the flashiest vehicle, but it was exactly what the U.S. Army needed—a tool that could be relied upon in the chaos of war. Today, the Jeep remains an icon, a symbol of ruggedness and American ingenuity born out of necessity.

The namesake has even become a special edition for the modern-day Wrangler. We’ve covered what the differences are in our article here.